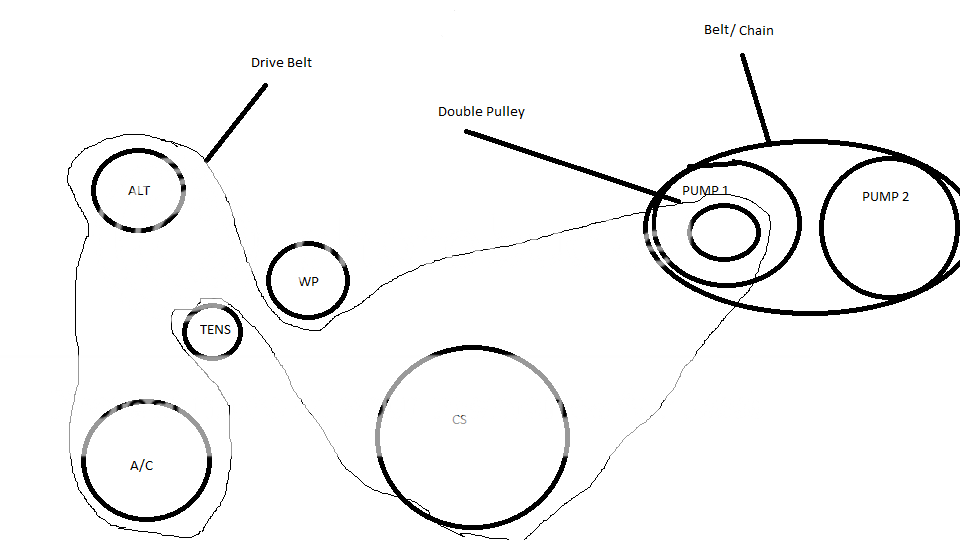

I was thinking of running the pumps on a custom made bracket in between the timing cover and the fender. Obviously this would mean moving the batteries and blocking off the hole in the timing case where the VE was on a stock engine. To run it the way i want to I would have to get rid of the fan and oil fill spout. I figure on running electric fans and relocating the oil fill. The thumbnail is how i propose to drive the pumps. The last pictue in the link below is what i would like to copy as close as possible.

http://www.thedieselpage.com/readers/kolkman.htm

First off, could you run them off of a normal serpentine style belt or would the belt slip on the pulleys and mess the timing up? If you could not run them off with a belt what would you do?

Second- The Ve runs at half of engine RPM at all times correct?

Third- How would a guy figure out what size the pulleys should be in order to run the pumps at the right speed?

Anything else you fellows think be sure to let me know- Thanks.

PS- I know this is a waste of time and money and a p-pump would be cheaper and make more power blah blah blah.