BC847 wrote:Y'all keep in mind: Basically, the spring is located between the throttle-lever, and the gizmo that moves the spill-port collar. When setting the throttle-lever indexing, you're basically wanting to take-up any slack between the throttle/spring/gizmo, . . .. without actually pulling on the gizmo (raising the fuel).

The 3800prm spring is in fact a little bit longer than the 3200rpm spring (stock spring too IIRC). It's been my experience that:

- If you're wanting to stay with the original throttle-lever indexing, you're gonna have to shorten the 3800rpm spring to match the original spring.

- If you don't shorten the 3800rpm spring, you'll have to re-index the throttle-lever so as to have full throttle available.

Make sense?

NOTE: That gizmo that the throttle tugs on with the spring, is also influenced by the fuel-screw and the governor mechanism.

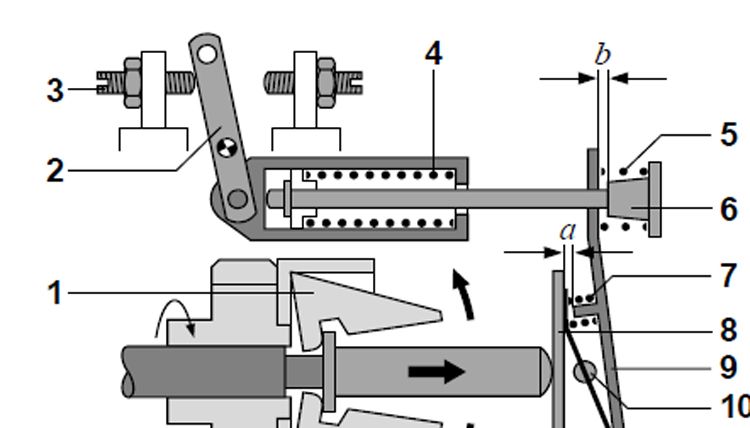

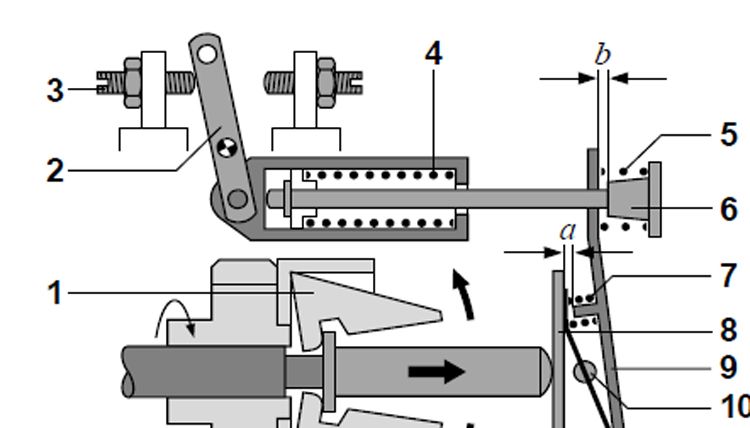

The typical governor spring in the center, throttle lever to the left, "Top-Hat" assembly to the right. That's the main fuel-screw to the upper-right of the Top-Hat assembly. That's the throttle-lever you're moving around indexing it to the shaft just above the number 3.

What-ever spring you put in, just make the spring fits with the change in lenght. The longer spring would need at least one more spline counter-clockwise.

NOTE: I personally back the main fuel-screw out three or four full turns when making changes to the throttle-shaft indexing. Once indexed where I want it, I then turn in the main fuel-screw 1/2 turn with each attempt to start the engine. You'll eventually have the engine try to idle (though stumbling) if not idling close to good.

Now adjust the main fuel-screw as you would otherwise. Run it in to maintain a maximum EGT at sustained WOT, our turn-up the flame to just before Run-Away.

If you run the main fuel-screw all the way in and your mess won't try to run-away? Then back the main fuel-screw out three or four turns, and re-index the throttle-shaft one more spline counter-clockwise. Now run the main fuel-screw in 1/2 turn at a time as before.

* I still have my fuel-kill pull-cable in my hand just in case. By now all of you should know how fast your engine will wind-up. You should be able to tell, when the engine first hits and turns over once or twice, if it's close to a normal idle, or headed to the moon. Just switch it off while pulling the cable it if even grins wrong at you. If you're here, in this site, in this thread, you should know the business-end of a wrench. There's really no excuse IMO for a run-away situation to occur if you do the main fuel-screw adjustment as I do. I've never had mine run-away, and yes, I've since found that spot where, with blipping the throttle, I'm thinking: Yeah, sure is slow at unwinding.

bgilbert wrote:I'm waiting on someone to try the min-max (VW) governor spring setup for competition applications, not necessarily for dyno purposes.

This is similar to what Bill's talking about. Instead of a simple governor-spring like we run, some VW applications use this type of governor assembly which actually has two springs as mentioned above. As I've read in the VW forums, it's common practice to shim the springs to raise the rev-limit.

Again, this image is only typical . . .

I'm gonna put together a thread directly of the typical VE fuel throttling (including the AFC) with more images like this.