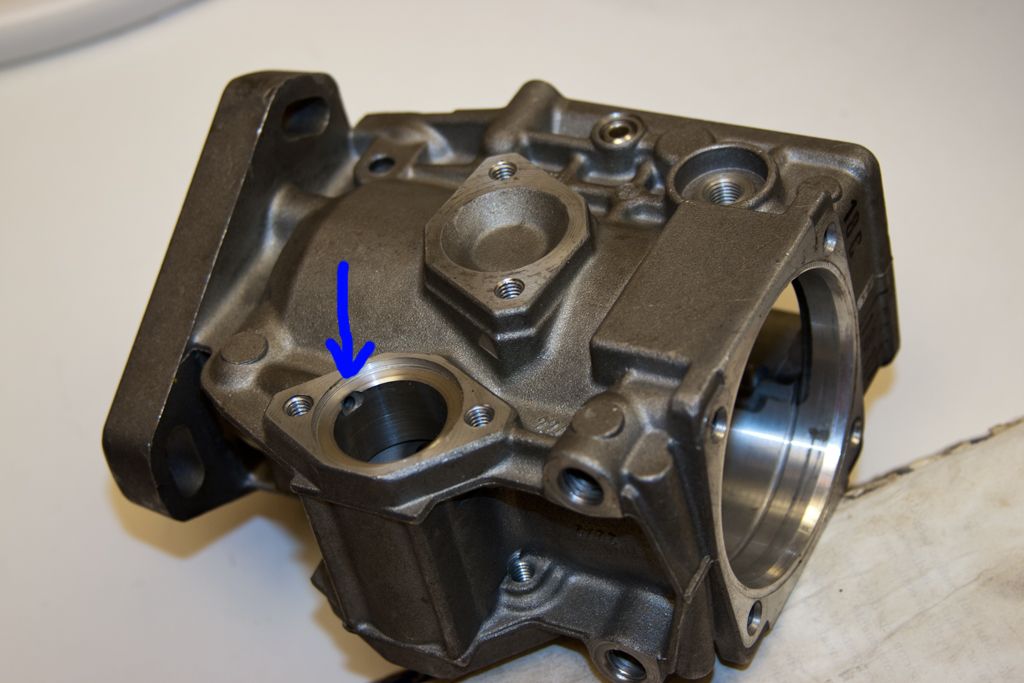

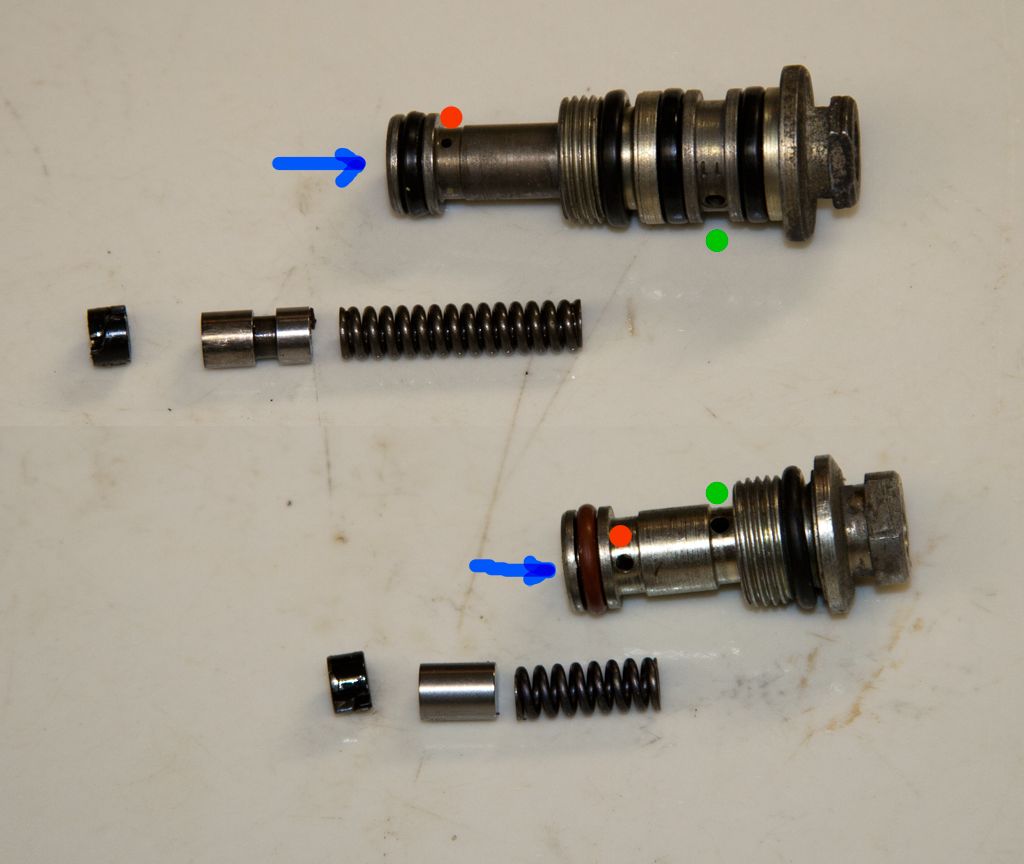

Overflow restriction

The overflow restriction (Figure 6) is screwed into the injection pump’s governor cover and connected to the pump’s interior. It permits a variable amount of fuel to return to the fuel tank through a narrow passage. For this fuel, the restriction represents a flow resistance that assists in maintaining the pressure inside the injection pump. Being as inside the pump a precisely defined pressure is required as a function of pump speed, the overflow restriction and the flow-control valve are precisely matched to each other.

It provides a means of minimum fuel flow for the purpose of cooling the IP as well.

Soo .. .. what if one were to modify one's existing restriction by adding an adjustable spring-loaded regulator in series?

- At a minimum fuel demand number (idle, light part-throttle maybe), the regulator would be open venting fuel from the restriction, back to the tank.

- Increasing the fuel demand greatly might drop case pressure having the regulator close. The idea being that fuel that would otherwise go to the tank, would be made available to the H/R (closing the return would help maintain a minimum case pressure).

I wonder how the dynamic injection event timing circuit would respond.

Looks like it has been done for specific applications:

Low-pressure stage

Low-pressure delivery

The low-pressure stage of a distributor pump fuel-injection installation comprises the fuel tank, fuel lines, fuel filter, vane-type fuel-supply pump, pressure control valve, and overflow restriction. The vane-type fuel-supply pump draws fuel from the fuel tank. It delivers a virtually constant flow of fuel per revolution to the interior of the injection pump. A pressure-control valve is fitted to ensure that a defined injection-pump interior pressure is maintained as a function of supply-pump speed. Using this valve, it is possible to set a defined pressure for a given speed. The pump’s interior pressure then increases in proportion to the speed (in other words, the higher the pump speed the higher the pump interior pressure). Some of the fuel flows through the pressure regulating valve and returns to the suction side. Some fuel also flows through the overflow restriction and back to the fuel tank in order to provide cooling and self-venting for the injection pump (Fig. 2). An overflow valve can be fitted instead of the overflow restriction.

Thoughts?