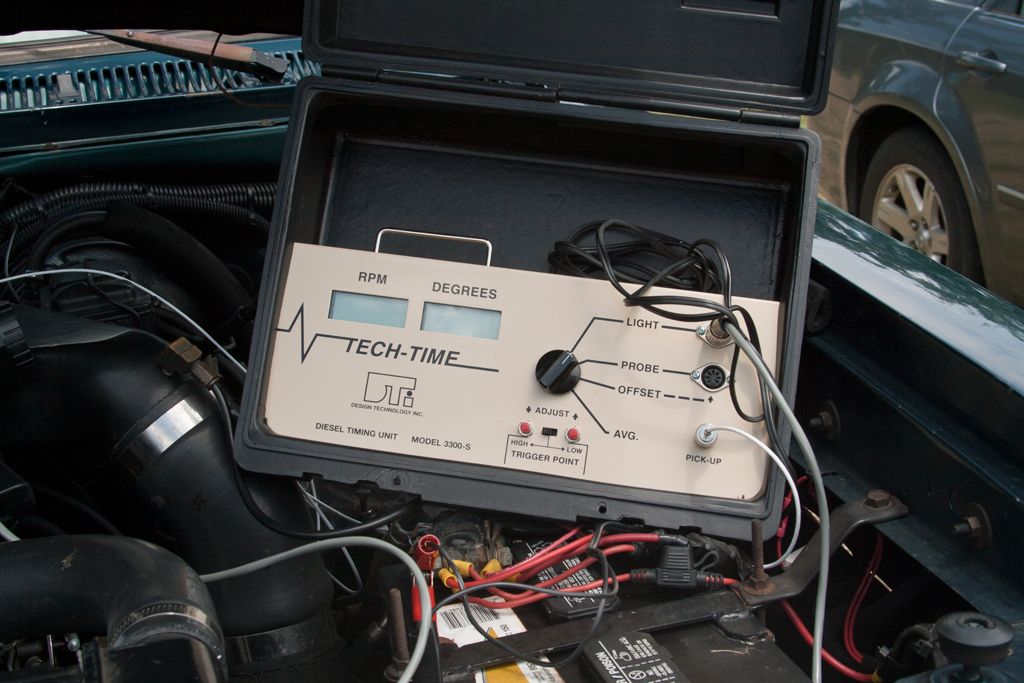

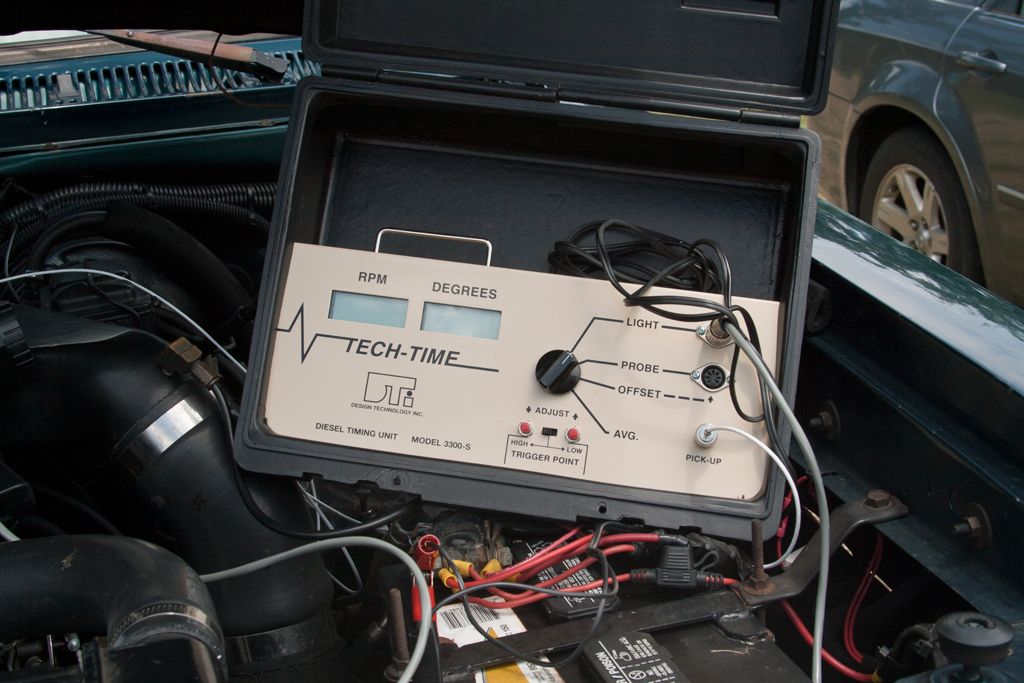

I've got the transducer located as close to the #1 injector as I can while staying on unbent piping.

The displays I've got available . . . .

This timing light doesn't work as easily as regular gas lights I've used in the past. You can't just pull the trigger and see where you are relative to the timing-tape. It turns out, I don't need a timing-tape at all.

This set-up apparently only sees one particular degree reading once it's dialed-in.

- To start with, see the little black slide-button, between the two red push-buttons above? Trigger-Point. What they're talking about is where the system recognizes the beginning of the injection event. Selecting LOW has the event beginning seen at about 30% of the pressure rise in the tube as is seen by the transducer. Selecting HIGH has the event beginning seen at about 70% of the pressure rise in the tube. The instruction manual says most manufacturers work with the LOW setting.

To make a reading:

- Connect stuff and start engine.

- Set desired engine RPM.

- With the engine rpm stable for over 5 or so seconds, the degree display will stop blinking.

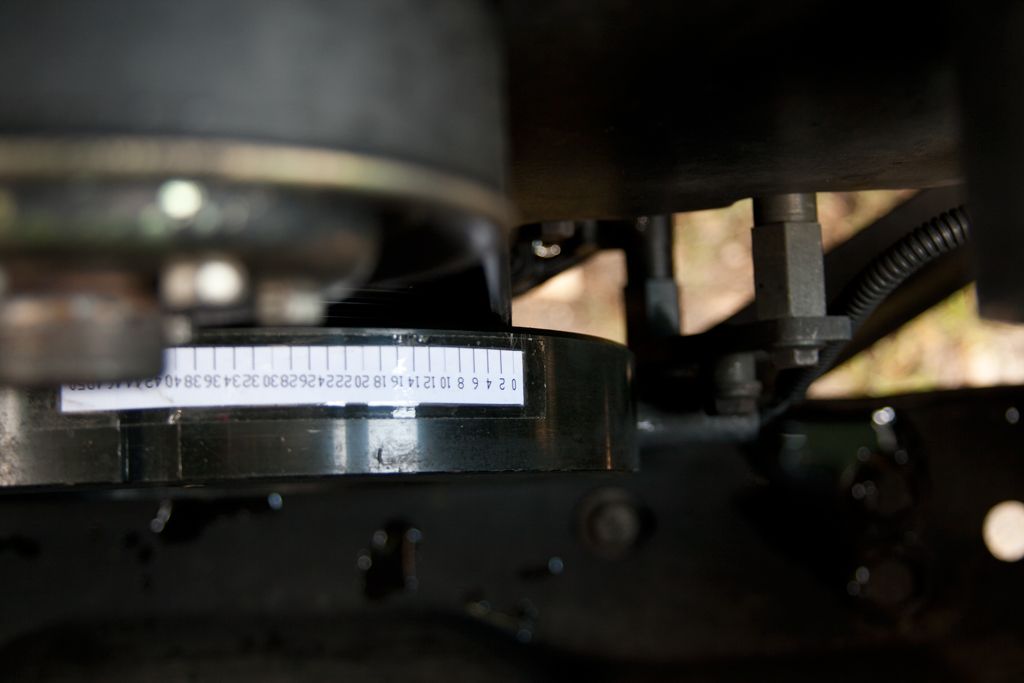

- Point the light where your pointer is. In my case, it's where the edge of the serpentine belt interfaces with the damper (or 0 degrees as shown by my timing-tape).

- Pulling the light's trigger will start the strobe-light.

- You'll notice right off, that the light shows the 0* mark WAY off to the left of the damper as you see it. Remember those two red push-buttons shown in the image above? While pulling the trigger, work either of those two push-buttons to move, or off-set, the 0 degree mark on the damper, over to the pointer.

NOTE: there are two little red push-buttons on the side of the gun allowing easy working while pointing the light, and pulling the trigger.

Having lined up the 0 degree mark with my pointer, the timing light says . .. . . .

As one looks at the truck as it stands, my injection event timing is at 18.5* BTDC @ 914 engine rpm.

This may take a few . . . . . hundred . . . . minutes to come up with plots.