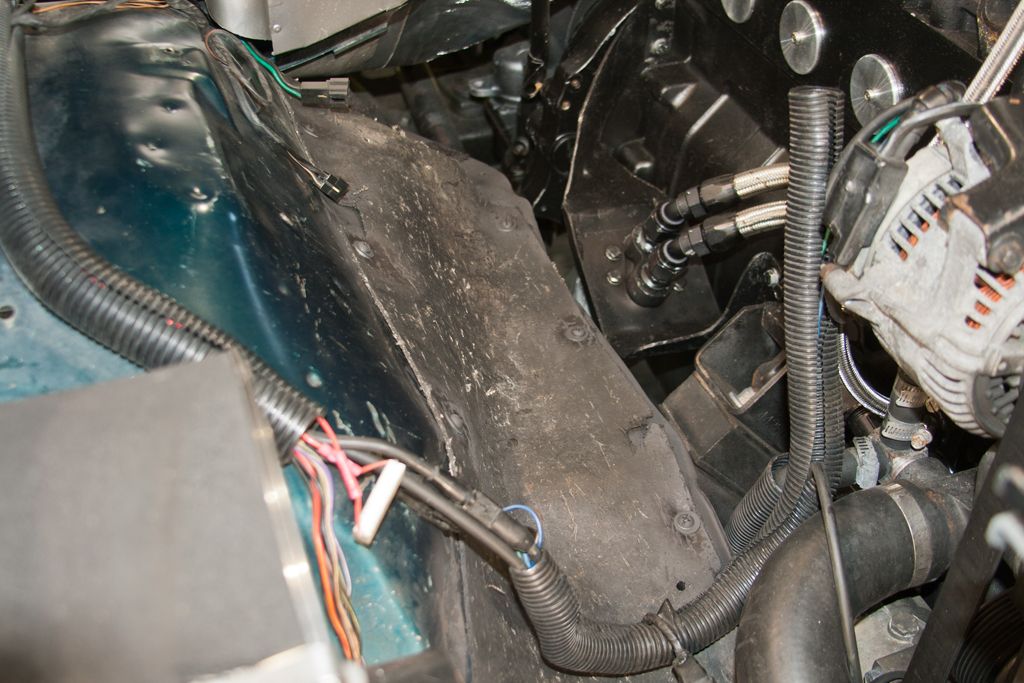

So, well over two years ago (Wed Sep 17, 2014 6:17 pm), I made a post talking about getting more air in my heap. With a LOT of input of most of our members during that time, I come up with this mess . . . . .

To start with, my wonderful Son, Adam, has been most gracious and is basically doing all the grunt-work of installing the sub-assemblies I've fabricated. . . . . . + I've no gaskets blown in my back, + he's on FB right now talking about his day literally installing trips on a 6bta.

Anyhoo, the man crawled his young skinny self right in there . . .

And started with chasing the exhaust manifold bolt holes on the head. Using a Q-Tip, he daubed a booger of nickle-based anti-seize in the threads.

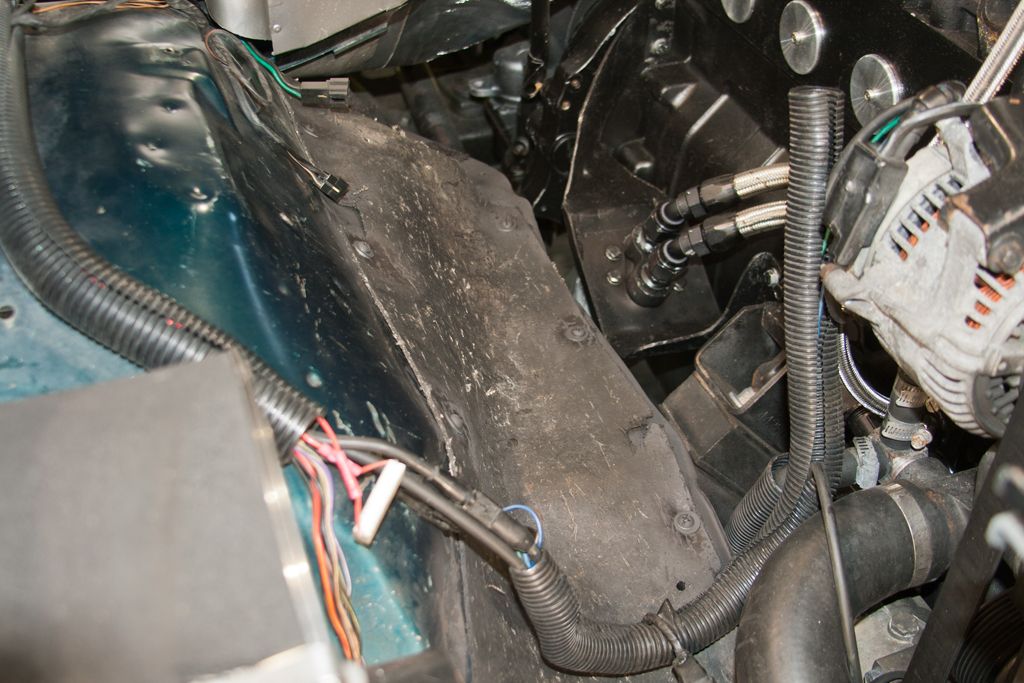

So, during all this, the rubber splash-shield eventually slipped out of place and his foot went through. Lets fix that he said . .

A number of well placed bolts, washers, etc later, it's done with a spot of flat black.

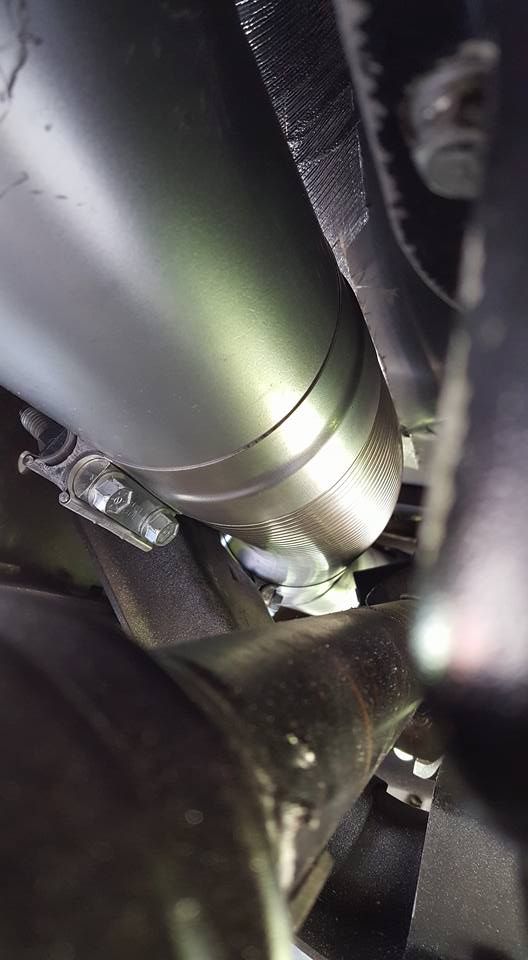

Alright, moving forward . . . . went to stabbing-in the new down-pipe and was reminded that, after five of so minutes move this way, and that way, that, there's a 27.04-step maneuver to get the stupid thing in there.

But before that, he, from under the truck went to bolt the transmission's fluid dip-stick to the bell-housing . . . and after a PITA ten minutes of dicking with it, realized that earlier, last week, when I tried simply blasting the dirt-daubers house from the bolt-holes with a garden hose, didn't get all of it. Adam's bolt was jamming in the bee-spit & Earth.

Had to back the bolt out, and using the proper tap, chase the two bolt-holes we're after.

Crap. Finally got the down-pipe and dip-stick nailed to the bell-housing . . .

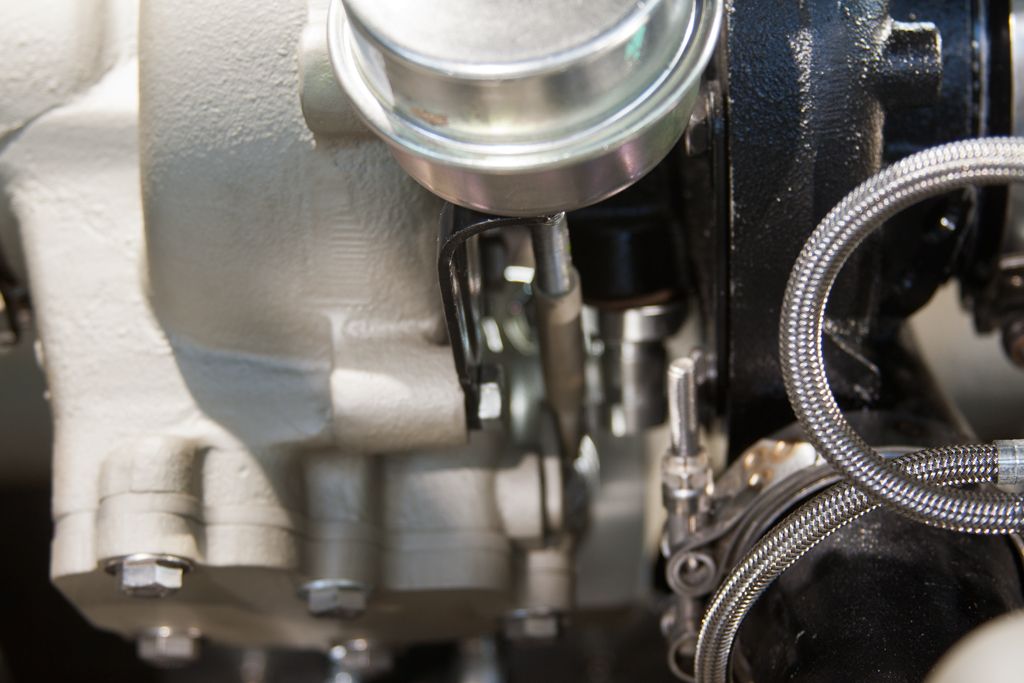

Now, moving on to installing the exhaust manifold, we used anti-seize on new Allen-headed stainless-steel bolts with split lock-washers. Brought them equally up to 20ft/lbs . . two consecutive rounds to ensure they're all equally at 20ft/lbs, then . . .. pulled them up to 32ft/lbs. All the while using the spiral from the center out, method.

BTW, those two bolts directly under the center section where the turbo sits? Yeah, there is NO Allen-headed socket-drive nothing that fits in there. It's my experience that you just have to suck it up and use two regular headed bolts there. And then only be able to pull them up with an open-ended wrench. Same thing with the ATP manifold I used with the former twins. Yes, I stole the two bolts from that mess.

Had to trim-to-fit the cab-heat hot water line's mount so it'd sit right in the new manifold's bolt slot thingy . . . .

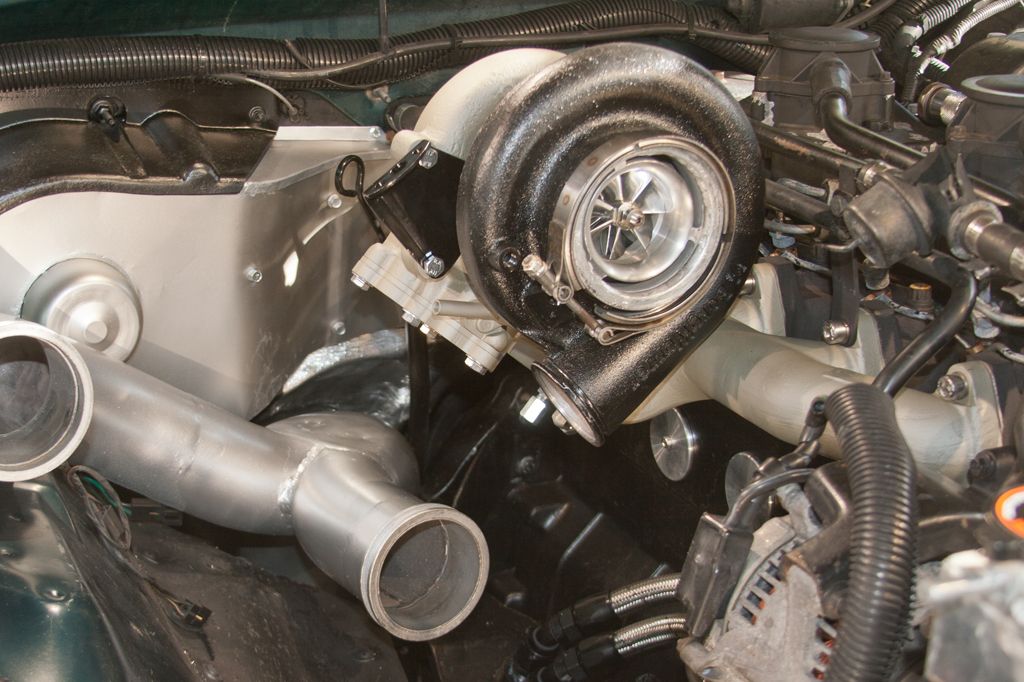

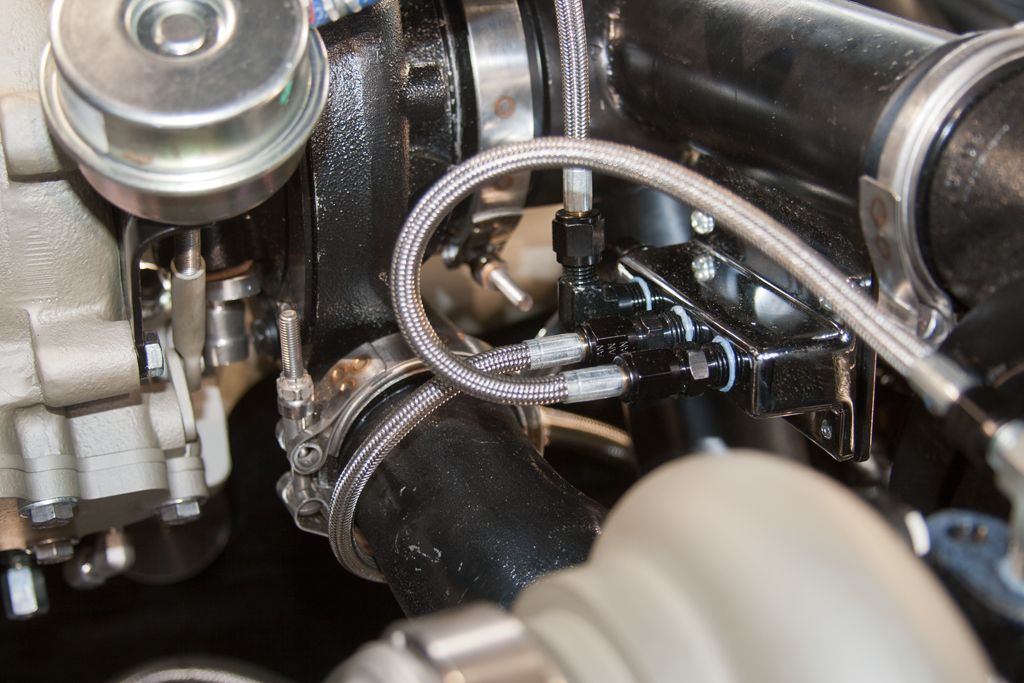

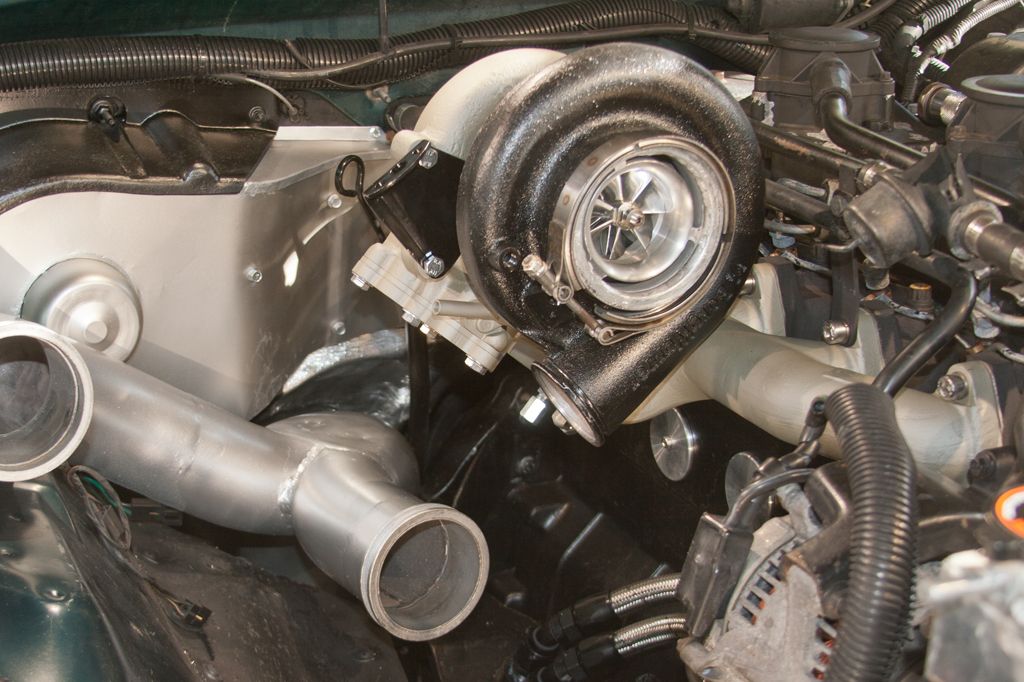

OK, fine, . . . . slathered the anti-seize on the studs for the secondary (they rusted a little, earlier when I had the mess on the engine for fabbing). Then mounted the secondary itself . . .

With that, it was time to hang the primaries . . . . . but wait! Let's slip in the new HVAC refrigerant hoses at the rear of the compressor. NO.

I got the correct size fittings for the hose and that at the ass of the compressor, . . . . but apparently/inadvertently interchanged the angles of the two. Won't fit like that. I'll have to get the correct - angle fittings and install the HVAC plumbing later.

. . . so, in goes the twin-primary assembly . . . ..

Tomorrow, God allowing, we'll . . . .

- Install the balance of the exhaust plumbing,

- Fabricate and install the turbo lube-oil drain-lines,

- Install and initially calibrate the secondary's waste-gate actuator,

- Plumb/install and connect the EGT sensor, drive-pressure sensor, and primary output pressure sensor,

- Fabricate and install the cold-pipe that's between the secondary's outlet and the IC's inlet.

- Add engine lube-oil, antifreeze, and . . . . . sthi! Charge the battery.

We'll see, huh?