compound or twins question

Moderators: Greenleaf, KTA, BC847, Richie O

20 posts

• Page 1 of 2 • 1, 2

compound or twins question

sorry maybe a stupid question but have been surfing thru old posts and am finding that some people are running the smaller turbo on top of the larger. why?. would you not want the smaller turbo to help spool the larger one or am i just missing somthing. you would still see boost of the smaller turbo and then the big one would lite. what am i missing. ie he35 under a ht3b. the 35 would help build that LARGE turbo would it not?

- truckwrench1

- fuel screw!!!!

- Posts: 53

- Joined: Sat Aug 07, 2010 6:09 pm

- Location: miami, oklahoma

Re: compound or twins question

truckwrench1 wrote:sorry maybe a stupid question but have been surfing thru old posts and am finding that some people are running the smaller turbo on top of the larger. why?. would you not want the smaller turbo to help spool the larger one or am i just missing somthing. you would still see boost of the smaller turbo and then the big one would lite. what am i missing. ie he35 under a ht3b. the 35 would help build that LARGE turbo would it not?

SPEAKING IN GENERAL TERMS . ..

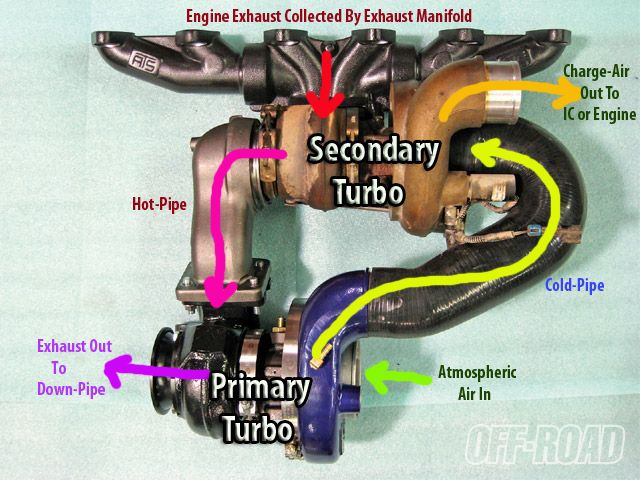

It helps to look at the sequential (proper terminology) turbochargers from two sides. The exhaust (hot) side, and the charge-air (cold) side. Further, the larger turbo is called the "Primary" or sometimes "atmospheric" turbo. The smaller turbo is called the "secondary".

The HOT side:

The hot, dense, high-pressure exhaust exits the exhaust manifold and enters the exhaust housing of the turbine of the secondary turbo. There, it expands and converts some of the energy of heat, into mechanical energy at the shaft (to be used by the compressor of the turbocharger).

The still quite hot, high-pressure gases then go to the primary turbocharger's exhaust housing where again, it expands and converts still more energy of heat to mechanical energy at the shaft (again, to be used by the compressor of the turbocharger).

- The hot expanding exhaust gases are the source of energy that power the compressors of the turbochargers no mater if it's one turbocharger, sequential, etc. The drop in EGTs that are commonly seen across a turbo illustrates this. 1200*F pre-turbo, 900*F post-turbo. That 300*F difference is the thermal energy converted to mechanical energy at the shaft.

- The use of turbochargers in general substantially increase the overall thermal efficiency of any engine as the energy of heat in the exhaust gases are otherwise wasted out the tail-pipe.

The COLD side:

The Primary turbocharger's compressor takes atmospheric air and compresses it to, let's say, 25psig. From there, the charge-air is fed to the Secondary, where it is still further compressed to 50psig.

The charge-air of the primary is of a larger volume (lower density) as compared to that same charge-air coming out of the Secondary (higher density), hence the Secondary having a smaller footprint. They both move the same original volume of air, it's just the increased density afterward results in a smaller apparent volume. (if that makes sense).

NOTE: Social terminology has confusing effects if not better understood. We DON'T run "Twins " on our trucks.

- Parallel turbos (true twins if you must) work side-by-side effectively splitting the work.

- Sequential turbos (what we use) have a larger turbo stuff a smaller turbo.

- Compound turbos work similarly to sequential turbos, but share a common shaft.

Hope this helps more than confuses.

David

1993 12mm VE Fueled W250 CC, Green

12.67 @ 103.35

Your basic farm truck ;)

1993 12mm VE Fueled W250 CC, Green

12.67 @ 103.35

Your basic farm truck ;)

- BC847

- Administrator

- Posts: 2205

- Joined: Wed Jan 03, 2007 5:22 pm