Called them and explained the problem. They asked to see pictures. I emailed them pictures of the problem. They called me back, and in the best english they could muster told me to GRIND THE LEDGE BY HAND?!?

ON A $400 PART?!?

Here are some pictures so that anyone else ordering from them may know what to expect.

First off a Bosch camplate:

Notice the OD of the ears is smooth all the way down

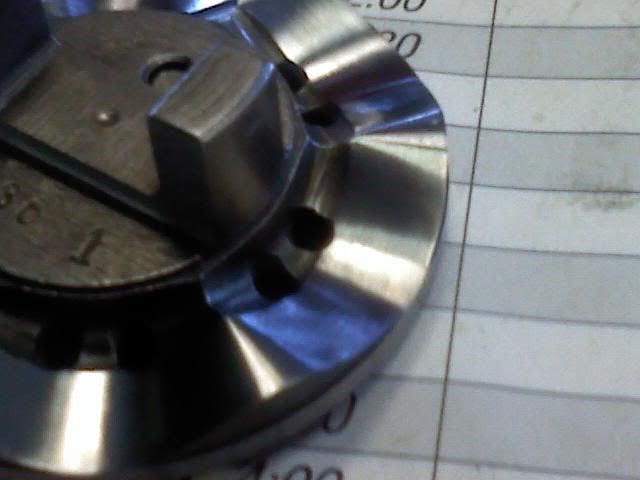

Next the Rockentech 4mm:

You can see the ledge at the bottom of the "ears" that runs all the way around.

And a couple of pictures of how it fits:

Well after their response, I took the parts to my favorite machine shop(not cheap, but VERY good), and am waiting to see what it will cost me to fix.