I've got a few so I'll number them for ya'll.

I've got a few so I'll number them for ya'll.

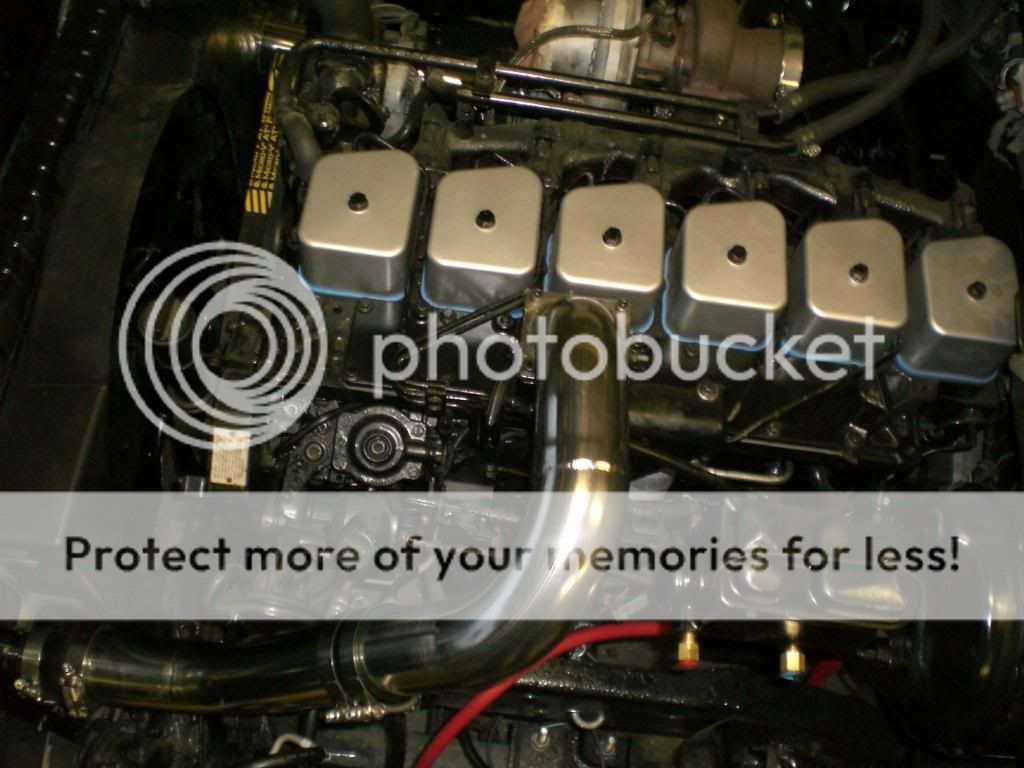

1. I've heard that the 24 valve intake horns work great for a non intercooled truck. HOW the heck do you get them to clear the brake master cylinder?

2. My truck parts junkyard got me a 1st gen intercooler, sizing it up i have 1/8 of an inch between the radiator side supports and the innermost part of the cooler. I don't want to mount it so close that my hump hoses will rub through.

About the truck, it's a 91 early model year, I'm using a HX35W and turbo outlet aluminum bend unit. made the executive decision to remove all the air conditioning bs to make more room. I'd rather my engine run cool than me. Any help or input on this project would be appreciated. I've lightly searched the forums and found a few posts but not much helpfull. Thanks a ton in advance.