Bottom Tapping

Moderators: Greenleaf, KTA, BC847, Richie O

15 posts

• Page 1 of 1

Bottom Tapping

Hi all,

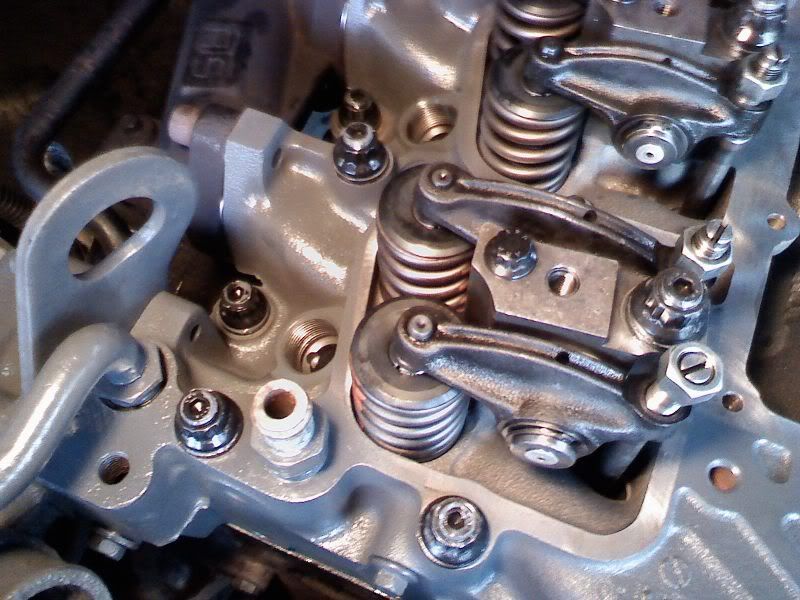

I am installing head studs and I was curious if you bottom tap all holes or just the 6 that go under the valve cover?

Thanks,

Bob

I am installing head studs and I was curious if you bottom tap all holes or just the 6 that go under the valve cover?

Thanks,

Bob

In Progress: '84 Chevy Silverado dually w/19.5 rims.

1st gen, New Eras, s300, 366, DennyT, piston LP, Pacbrake, 60lbs. springs, ARP studs, Snow Perf. stage II, '97 DR IC, 4" stacks.

NV4500, 14 Bolt Locker & Dana 60 Posi w/3.73's

1st gen, New Eras, s300, 366, DennyT, piston LP, Pacbrake, 60lbs. springs, ARP studs, Snow Perf. stage II, '97 DR IC, 4" stacks.

NV4500, 14 Bolt Locker & Dana 60 Posi w/3.73's

-

MrHorsepower - fuel screw!!!!

- Posts: 69

- Joined: Wed Jan 07, 2009 5:04 pm

- Location: Avoca, NY