Fuel PIn Questions

Moderators: Greenleaf, KTA, BC847, Richie O

12 posts

• Page 1 of 1

Fuel PIn Questions

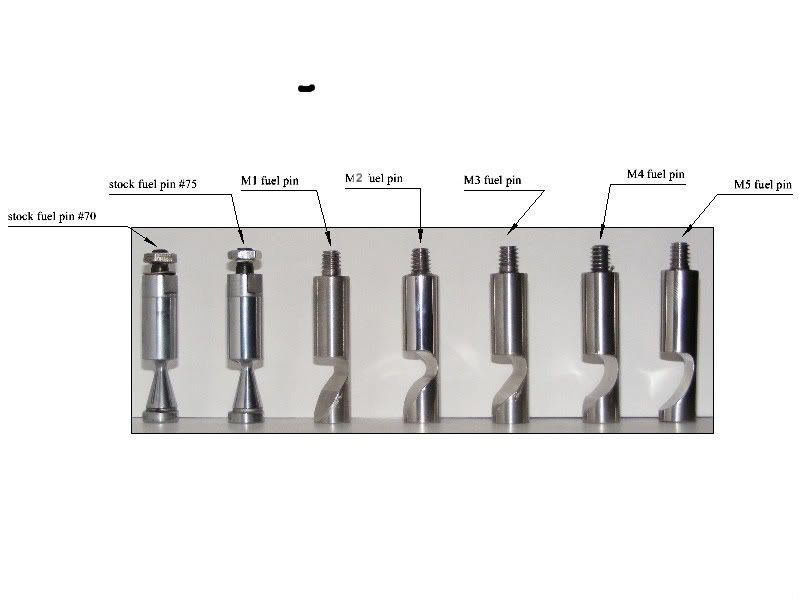

How far can the pin that rides on the fuel pin travel outwards before ruining the seal? Also how far does the fuel pin itself travel downwards? What Type of steel do I need to use to make a fuel pin? Sorry for so many questions but trying to make my own Fuel Pin so Any specifications or tips are greatly appreciated.

90 W250 4x4 5spd pump Ve cranked wide open, BHAF, HX35 with all 2.5" intake piping, and 4" straight piped

92 W250 4x4 5spd P-pumped B1B over B2 are on and now slippy clutch

92 W250 4x4 5spd P-pumped B1B over B2 are on and now slippy clutch

- cedardiesel

- fuel screw!!!!

- Posts: 141

- Joined: Fri Jun 20, 2008 8:49 pm

- Location: Lebanon

I do know it has to be wicked hard steel. ( we say wicked in Maine )  The soft steel grooves easy. I saw a pic of a aftermarket pin that had a good groove worn in it.

The soft steel grooves easy. I saw a pic of a aftermarket pin that had a good groove worn in it.

Last edited by Richie O on Thu Jan 22, 2009 11:09 pm, edited 1 time in total.

1989 W250 727, 3.07 L/S, S300, P/S Intercooler, Stans exaust, Pump adjustments, 127k miles,297 hp

1993 W250 extended cab, rag, 4.10 l/s, 6x16's, HTT 62/71/14 piston l/p, Isspro EV series tach, fuel pressure, boost, oil pres, water temp, volt, pryo, 132k/ 301 hp

1992 W250 with NV4500, 3.54's, 16cm 60mm GDS H1C, ground stock cone, Isspro tach, pryo, boost, fuel pressure, slow, rusty, dented,180k

1993 W250 extended cab, rag, 4.10 l/s, 6x16's, HTT 62/71/14 piston l/p, Isspro EV series tach, fuel pressure, boost, oil pres, water temp, volt, pryo, 132k/ 301 hp

1992 W250 with NV4500, 3.54's, 16cm 60mm GDS H1C, ground stock cone, Isspro tach, pryo, boost, fuel pressure, slow, rusty, dented,180k

-

Richie O - Administrator

- Posts: 4171

- Joined: Sat May 17, 2008 9:01 pm

- Location: New England