pump install

Moderators: Greenleaf, KTA, BC847, Richie O

22 posts

• Page 1 of 2 • 1, 2

pump install

Ok so its time to install my new injection pump

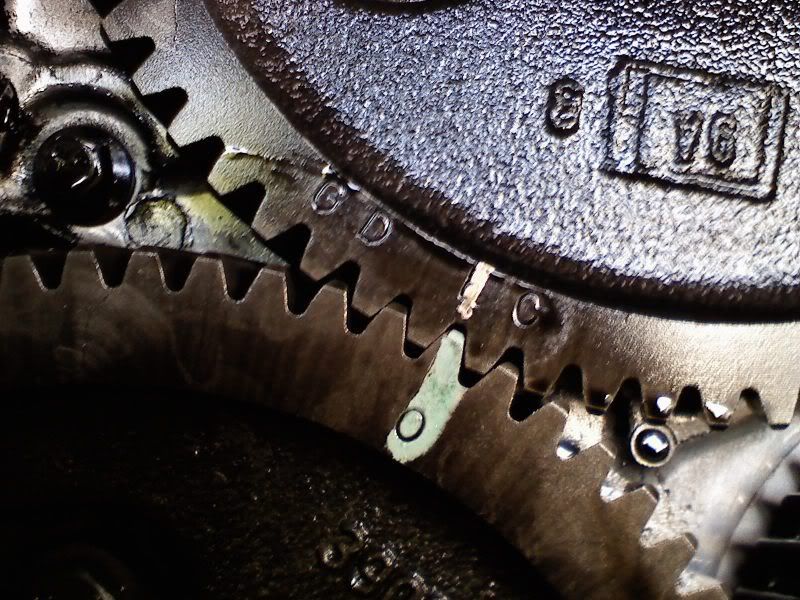

I know motor has to be tdc, and all the marks lined up on the gears

but is it possible to be 360 degrees out or one cycle?

if so how does one make sure that your on the right tdc cycle before installing the pump

thanx

I know motor has to be tdc, and all the marks lined up on the gears

but is it possible to be 360 degrees out or one cycle?

if so how does one make sure that your on the right tdc cycle before installing the pump

thanx

91 F350 5.9 Cummins, Custom built VE 12v

Sponsors of new truck

Performance Diesel Injection

Colt Cams

H&H Offroad

Arties Transmission

Toms Contracting

Sponsors of new truck

Performance Diesel Injection

Colt Cams

H&H Offroad

Arties Transmission

Toms Contracting

- seeker1056

- 14mm rotor

- Posts: 506

- Joined: Tue Mar 06, 2007 7:19 pm

- Location: Lakefield Ontario Canada

If all the marks are lined up, you can put the pump right in. The pump gear turns at cam speed, so you can't be off 360. Just make sure you have the correct letter lined up with the cam mark. If you're not sure, I posted what mark is for what engine on here someplace.

pete

Just enough power to break everything behind the crankshaft.

Just enough power to break everything behind the crankshaft.

-

PToombs - 14mm rotor

- Posts: 11369

- Joined: Sun Jan 07, 2007 6:13 pm

- Location: Syracuse NY. Snow central!