by Remps » Fri Dec 04, 2009 10:43 am

by Remps » Fri Dec 04, 2009 10:43 am

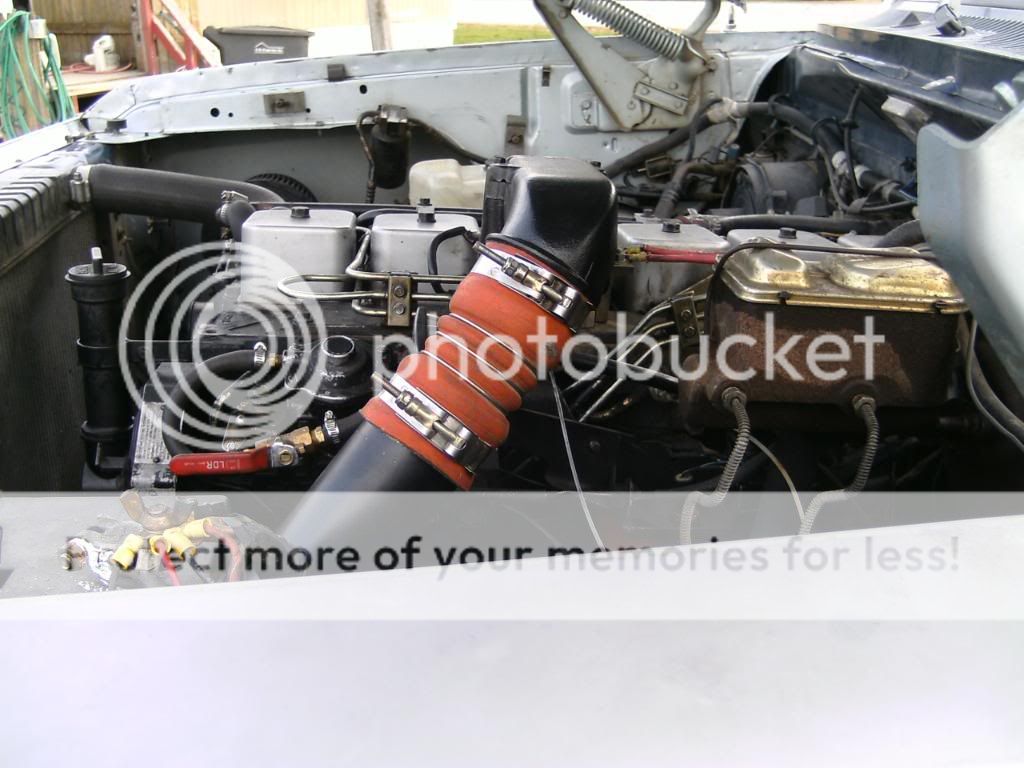

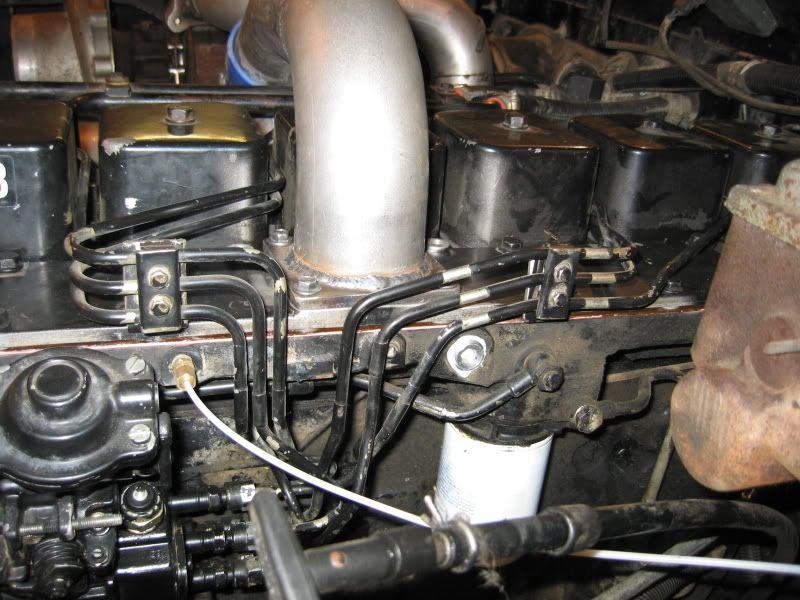

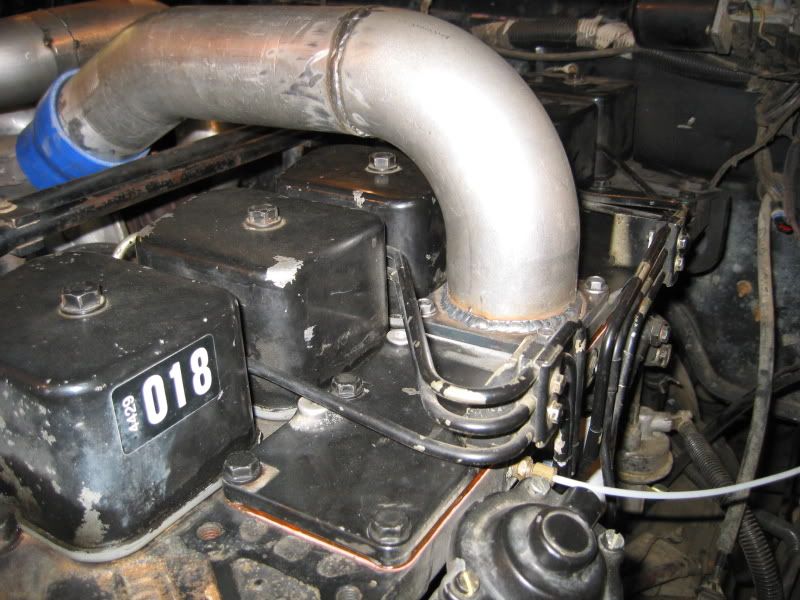

You don't have to switch throttle brackets,just notch it out so you can fit I/C airhorn on,and bolt back on.(I THINK it would bolt back on if you did it right,I cut it off with a side grinder on the bend,and wedged the bracket under the airhorn)The manifold also does not have to be flipped,but you will have to run a bit longer I/C boot to reach the airhorn,and it rides pretty close to the brake reservoir.I like how the N/IC manifold is dead center,so I left mine.Just my .02.

'90 D250 R/C,727,IC,6x.009's,1/8" bump,fuel psi,straight pipe w/5" stack.

'90 W250 R/C,47rh,K@N,HX35,1/8" bump,2nd gen IC,boost,egt,trans temp.3.07's.

'96 2500 S/C L/B,2wd,NV5600,3.54 L/S,cai,egt,pacbrake,mbrp exhaust,10 plate.

Bring back the Bank of Canada, PRE- 1974.