serpentine belt problems

Moderators: Greenleaf, KTA, BC847, Richie O

10 posts

• Page 1 of 1

serpentine belt problems

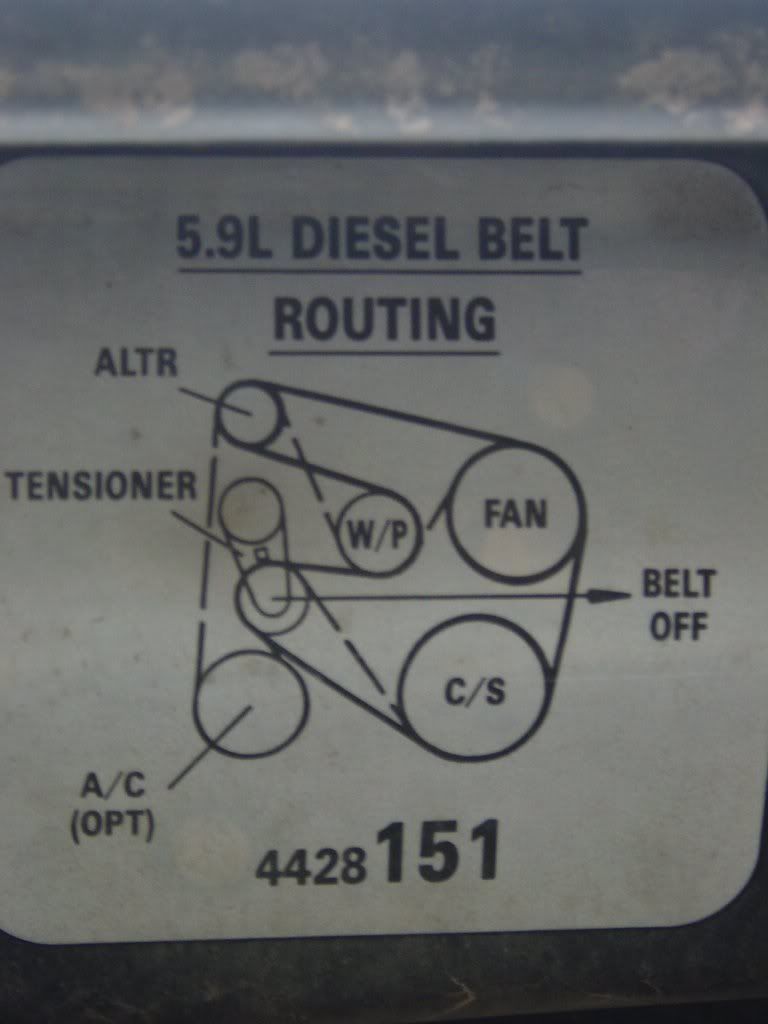

Ok, I got the non air belt and tried putting it on, while it's a good bit shorter than the air version belt it's still that new railroad, Norfolk and Way. you sure there's not an extra idler I need to do the switch?

93 w250 6 speed 4" exhaust, caution, work truck, she's no beauty. building 1 ton dually 4x4, dana 80, 48rh, 205 Scratch the one ton, bought frt. dually 4x4 98 12 valve with the tiny rear doors. rides so much better than the 93.

- txs

- 14mm rotor

- Posts: 556

- Joined: Sat Sep 29, 2007 7:48 am

- Location: south cumberland plateau, tenn

The nonAC belt is routed a different way. You probly don't have a diagram eh? Maybe someone can post one for ya, I've seen it online before.

Bill Gilbert

85 D350 crew with 90 6BT intercooled Getrag 3.07's

93 D350 single cab Getrag 3.54's.

85 D350 crew with 90 6BT intercooled Getrag 3.07's

93 D350 single cab Getrag 3.54's.

- bgilbert

- 14mm rotor

- Posts: 2253

- Joined: Wed Jan 03, 2007 5:04 pm

- Location: Terre Haute, Indiana