Front Pump Seal

Moderators: Greenleaf, KTA, BC847, Richie O

28 posts

• Page 1 of 2 • 1, 2

Front Pump Seal

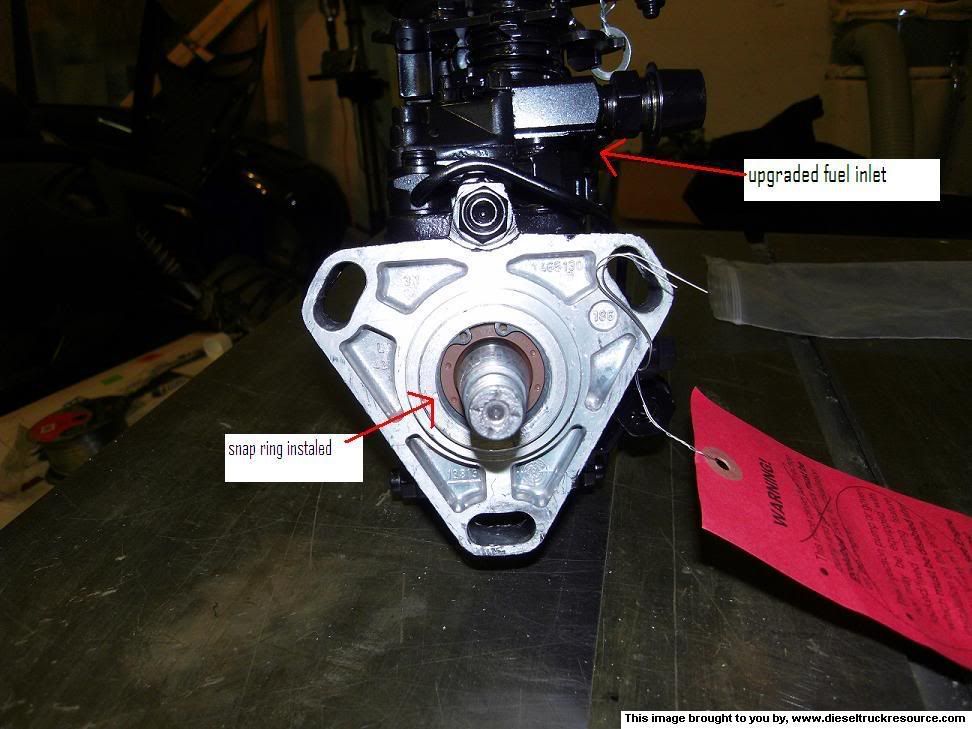

Well I have teh whole front of teh truck torn off to swap in a I/C'ed front end and figure while its off I'll make my life easy. Gonna do the KDP, Jump a tooth or two on the pump, and take care of the pumps front seal.

I got teh first two down, but being as how I have never even SEEN teh front seal i have not a clue. I think i want to machine it and put in a snap ring. Anyone have any pictures?

I got teh first two down, but being as how I have never even SEEN teh front seal i have not a clue. I think i want to machine it and put in a snap ring. Anyone have any pictures?

-

RSWORDS - 14mm rotor

- Posts: 820

- Joined: Fri Feb 29, 2008 8:00 pm