Fuel pressure question

Moderators: Greenleaf, KTA, BC847, Richie O

26 posts

• Page 1 of 2 • 1, 2

Fuel pressure question

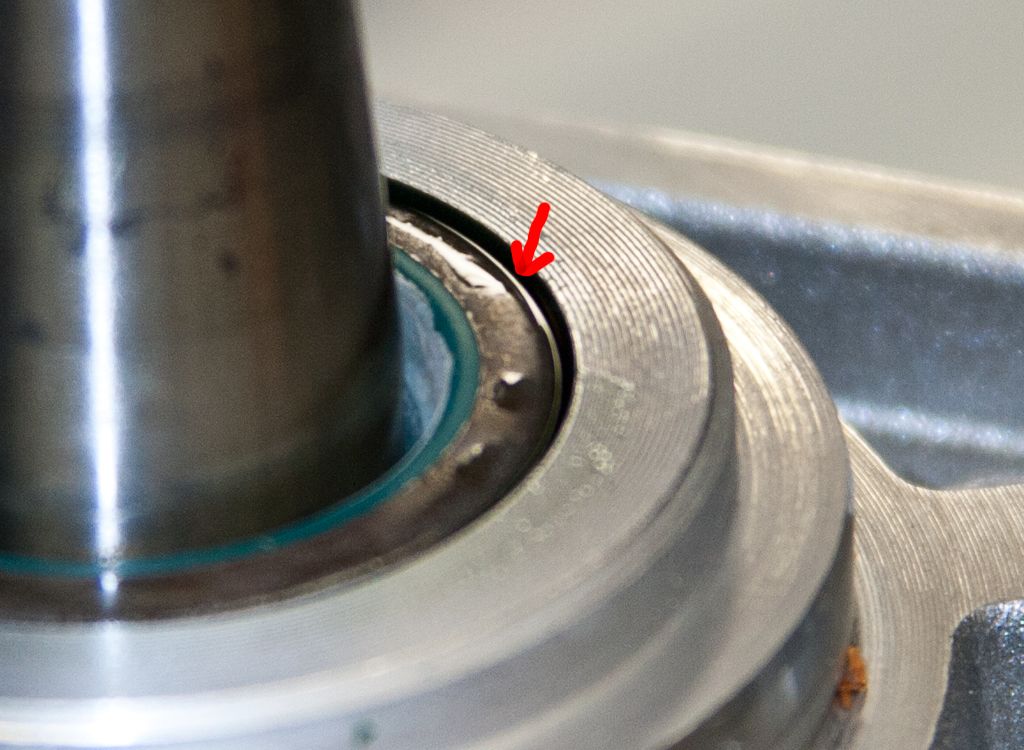

What is the highest psi I can run at an idle and at WOT w a non lock tire seal ve?

- cummins12club

- fuel screw!!!!

- Posts: 271

- Joined: Wed Aug 08, 2012 2:43 pm

Re: Fuel pressure question

15psi is the safe number.

Derek B.

2003 QuadCab, Tater 62/65 341cw, Smarty Touch SW9, Full Billet trans.

91.5 W250, coolertubz, HE351CW, PS IC, Alcans, GVOD, Valair DD, bags, crossover.

1974 Pontiac Ventura,best of 11.97 at 112 so far.

Aluminum heads and roller cam on the way.

2003 QuadCab, Tater 62/65 341cw, Smarty Touch SW9, Full Billet trans.

91.5 W250, coolertubz, HE351CW, PS IC, Alcans, GVOD, Valair DD, bags, crossover.

1974 Pontiac Ventura,best of 11.97 at 112 so far.

Aluminum heads and roller cam on the way.

-

BILTIT - 14mm rotor

- Posts: 711

- Joined: Wed Aug 11, 2010 1:29 pm

- Location: Lloydminster, Saskatchewan